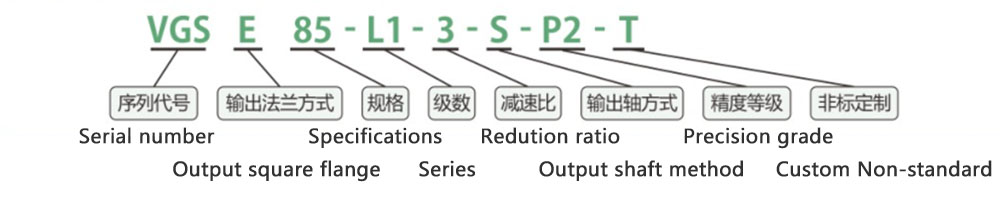

Reducer Model Description

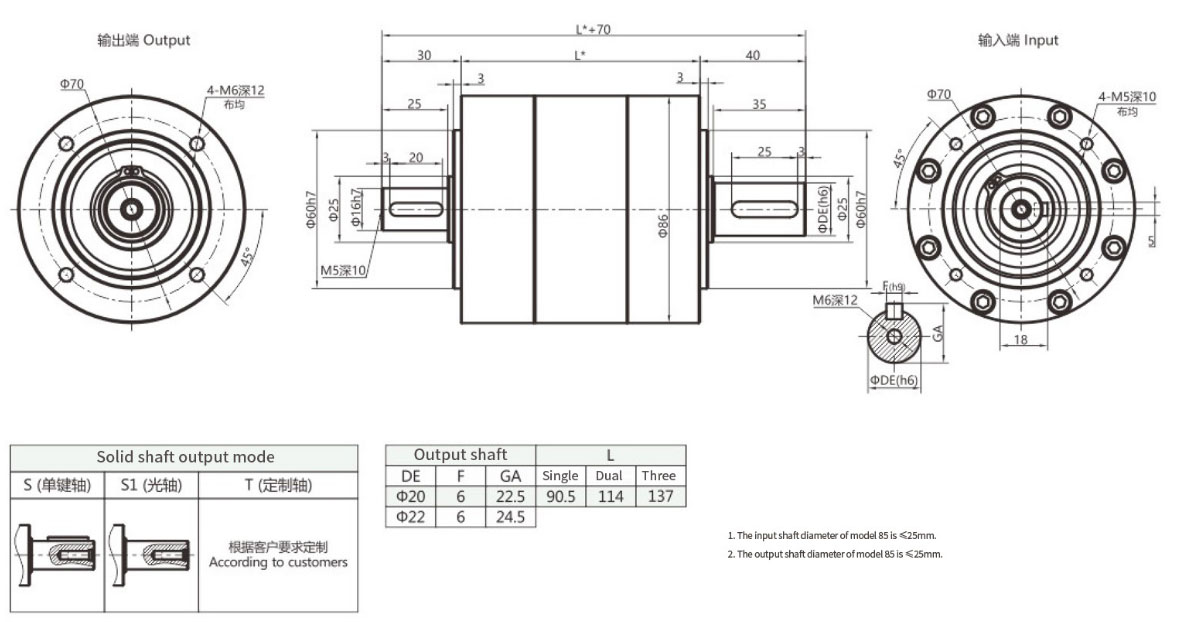

Dimensions of the Reducer

Reduction Ratio

| Series | Single-stage | Dual-stage | Three-stage | ||||||||||||||||||||||

| Ratio | Recommended | 16 | 25 | 28 | 80 | 125 | 200 | 250 | |||||||||||||||||

| 3 | 4 | 5 | 7 | 10 | 12 | 15 | 20 | 35 | 40 | 50 | 70 | 60 | 100 | 140 | 175 | 280 | 350 | 400 | 500 | 700 | 1000 | ||||

| Not recommended | 30 | 100 | |||||||||||||||||||||||

| Normail torque | Nm | 60.0 | 88.0 | 95.0 | 66.0 | 40.0 | 98.0 | 105.0 | 98.0 | 105.0 | 60.0 | 98.0 | 105.0 | 70.0 | 40.0 | 98.0 | 125.0 | 125.0 | 135.0 | 125.0 | 135.0 | 125.0 | 135.0 | 93.0 | 58.0 |

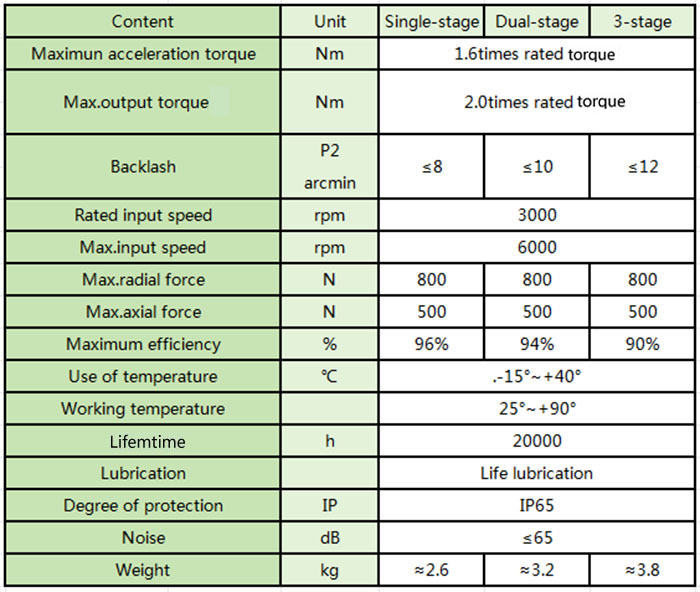

Reducer Parameters

*1. Ratio i=Nin/Nout(Input speed/output speed)

*2. When the speed of the output shaft of the reducer is 100r/min,it acts on the midpoint of the output shaft of the reducer, and the direction of action is perpendicular to the output shaft, meeting the maximum radial force that the output shaft can withstand when the life of the reducer is 20000H.

*3. High/low temperature grease can be customized according to the use environment.

+86-18664078178

+86-18664078178  Email

Email