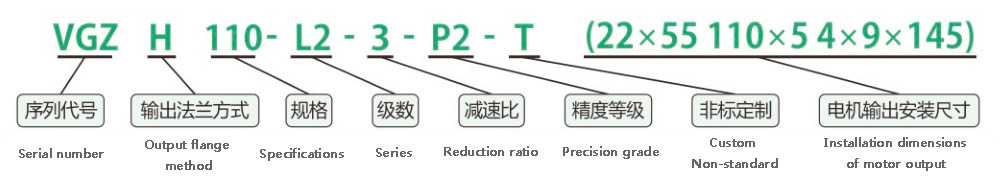

Reducer model desciption

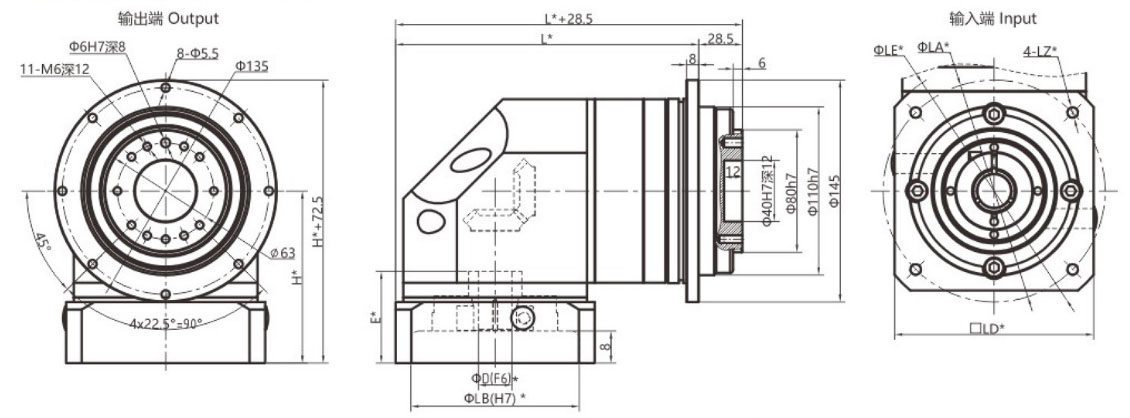

Dimensions of the Reducer

| Adapted motor | ||||||||||

| Specifications | ΦD | E | LB | LZ | LA | LE | LD | H | L | |

| Single | Dual | |||||||||

| 750W Servo | Φ19 | 47 | Φ70 | 4-M5/M6 | Φ90 | Φ160 | 120*120 | 99.5 | 193 | 223 |

| 1500W Servo | Φ19 | 60 | Φ95 | 4-M8 | Φ130 | Φ160 | 120*120 | 112.5 | 198 | 228 |

| Φ22 | 60 | Φ110 | 4-M8 | Φ145 | Φ170 | 130*130 | 112.5 | 198 | 228 | |

| 110 Stepper | Φ19 | 60 | Φ85 | 4-M8 | Φ132(93.3*93.3) | Φ160 | 120*120 | 112.5 | 198 | 228 |

| 130 Stepper | Φ19 | 56 | Φ100 | 4-M10 | Φ155(109.6*109.6) | Φ176 | 130*130 | 108.5 | 198 | 228 |

1. Dimensions marked with * vary depending on the installed motor.

2. The input shaft diameter of model 115 is ≤24mm, and input with key is optional.

3. There is no single-stage version of the 115 angle type.

Reduction Ratio

| Series | Single-stage | Dual-stage | Three-stage | ||||||||||||||||

| Ratio | Recommended | 16 | 25 | 28 | 80 | 125 | 200 | 250 | |||||||||||

| 12 | 15 | 20 | 35 | 40 | 50 | 70 | 60 | 100 | 140 | 175 | 280 | 350 | 400 | 500 | 700 | 1000 | |||

| Not recommended | 100 | 30 |

Enquiry | ||||||||||||||||

+86-18664078178

+86-18664078178  Email

Email