It has many significant features and advantages. First, the planetary reducer has extremely high transmission efficiency, which can effectively convert input power into output and reduce energy loss. Secondly, it has strong carrying capacity and can withstand large loads, which is suitable for various heavy industrial equipment. Moreover, its structure is compact, the volume is relatively small, it takes up less space, and it is easy to install and layout.

Following are the general assembly steps for planetary reducers:

Preparation:

Clean the work area to ensure that there is no dust and impurities.

Prepare the required tools, such as wrenches, screwdrivers, etc.

Check that all parts are complete and undamaged.

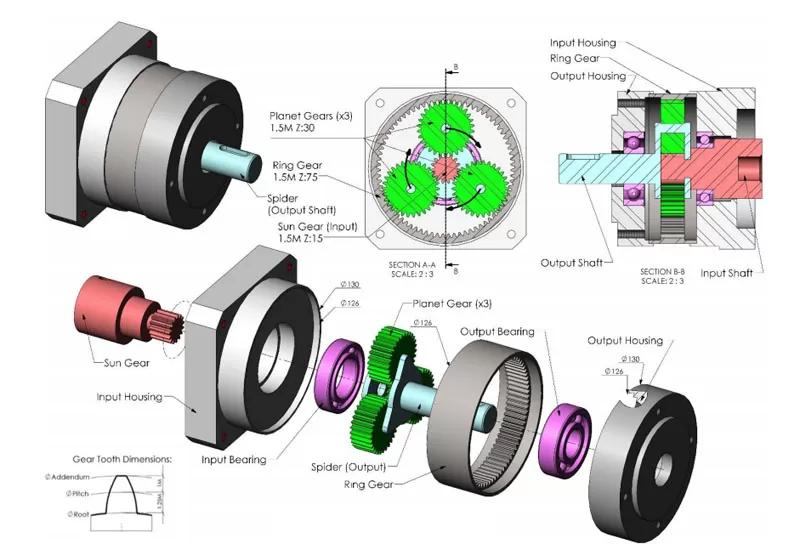

Install the sun gear:

Place the sun gear in the center of the reducer and ensure that its installation position is accurate.

Install the planetary gears:

Distribute the planetary gears evenly around the sun gear and ensure that they can rotate smoothly.

Install the planetary carrier:

Install the planetary carrier on the planetary gears so that the planetary gears are tightly combined with the planetary carrier.

Install the inner ring gear:

Carefully install the inner ring gear in place and properly mesh with the planetary gears.

Install the output shaft:

Ensure that the output shaft is accurately connected to other components and can rotate freely.

Install the oil seal and seal:

Install the oil seal and seal in the correct way to prevent lubricant leakage.

Add lubricant:

Add an appropriate amount of lubricant according to the specifications and requirements of the reducer.

Inspection and debugging:

Turn the input and output shafts of the reducer manually to check for any jamming or abnormal sounds.

Check the tightness of each connection part.

Housing installation:

Install the housing of the reducer and make sure all screws are tightened.

It should be noted that planetary reducers of different models and specifications may differ in assembly details, so be sure to read the relevant assembly instructions and technical requirements carefully before assembly. For example, some high-precision planetary reducers require special fixtures to ensure installation accuracy when assembling planetary gears and sun gears. In addition, after assembly, a period of no-load test run is required to ensure the performance and stability of the reducer.

+86-18664078178

+86-18664078178  Email

Email