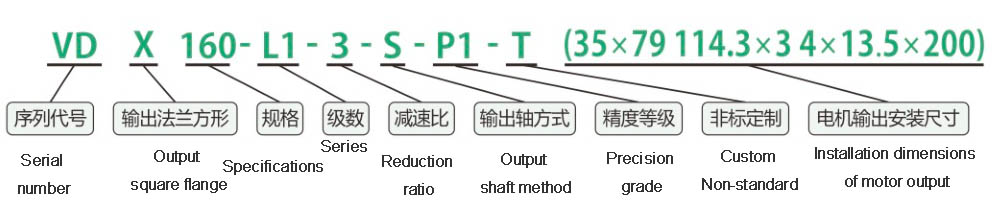

Reducer Model Description

● Gears:

with helical gear design, the gear meshing rate is more than twice the normal gear, with smooth running, low noise,high output torque, and low backlash. The gears adopt special grease lubrication and IP65 protection grade seal design, the output shaft surface is of polishing treatment, and adopt reasonable tolerance. Ensure minimum friction coefficient and reduce startup load. No oil leakage or maintenance in service life in any direction.

● Output planet rack:

the planetary arm frame and the output shaft adopt integrated design. Before and after bearing large span is distributed in the box body, forming a stable one-piece structure. Ensure high torsion stiffness and accuracy. Adjust the axial clearance through the adjustment sleeve on the planetary shelf.

● Output inner ring:

the tooth ring and the output side shell adopts the integral design, adopt the high quality steel, through hot forging forming, thus obtain the higher material density. The integrated design ensures that all geometric dimensions are processed at one time, with higher precision and strength than other embedded and clamped structures.

● Input shaft:

input shaft and the locking device adopts integrated design, double bolt symmetric distribution, to achieve the dynamic balance at the same time, through double bolt strong lock, effectively prevent motor shaft driving sliding, achieve high accuracy zero back power transmission.

● Install flange:

advanced connecting plate design, easy to install with various factory brand servo, stepping motor perfectly.

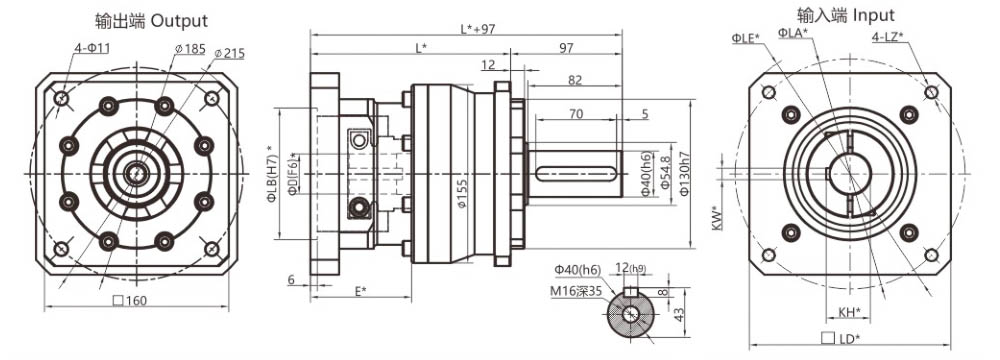

Dimensions of the Reducer

| Adapted motor | |||||||||||

| Specification | ΦD | E | LB | LZ | LA | LE | LD | KW | KH | L | |

| Single | Dual | ||||||||||

| 1500W Servo | Ø22 | 63 | Ø110 | 4-M8 | Ø145 | Φ165 | 130*130 | — | — | 149 | 188.5 |

| 2000W Servo | Ø35 | 88 | Ø114.3 | 4-M12 | Ø200 | Ø230 | 175*175 | 10 | 38.3 | 174 | 3.5 |

| 7500W Servo | Ø38 | 88 | Ø180 | 4-M12 | Ø215 | Ø230 | 190*190 | 10 | 41.3 | 174 | 213.5 |

| Ø42 | 118 | Ø114.3 | 4-M12 | Ø200 | Ø230 | 175*175 | 12 | 45.3 | 204 | 243.5 | |

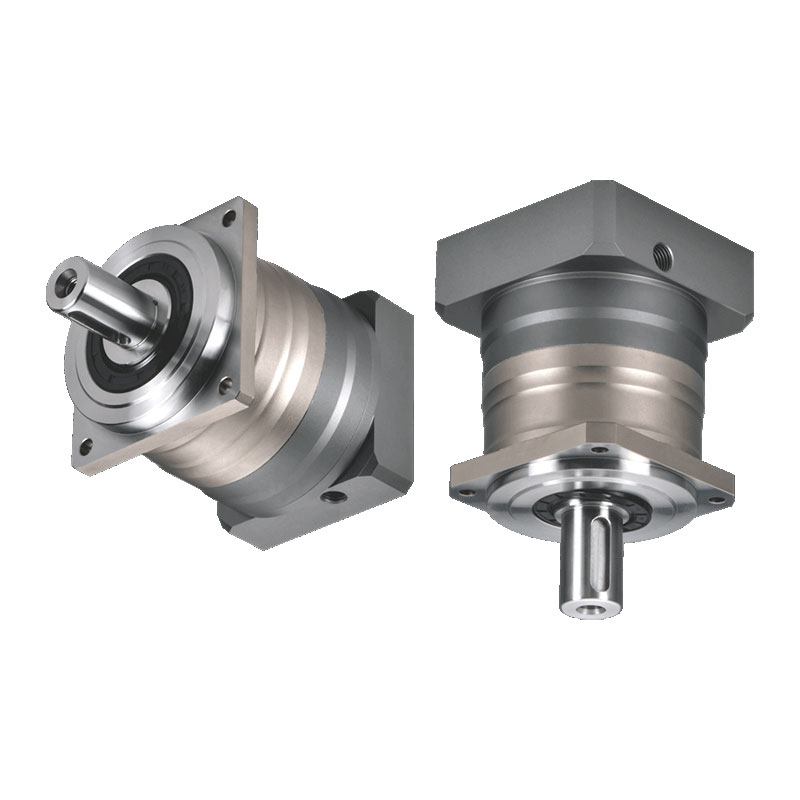

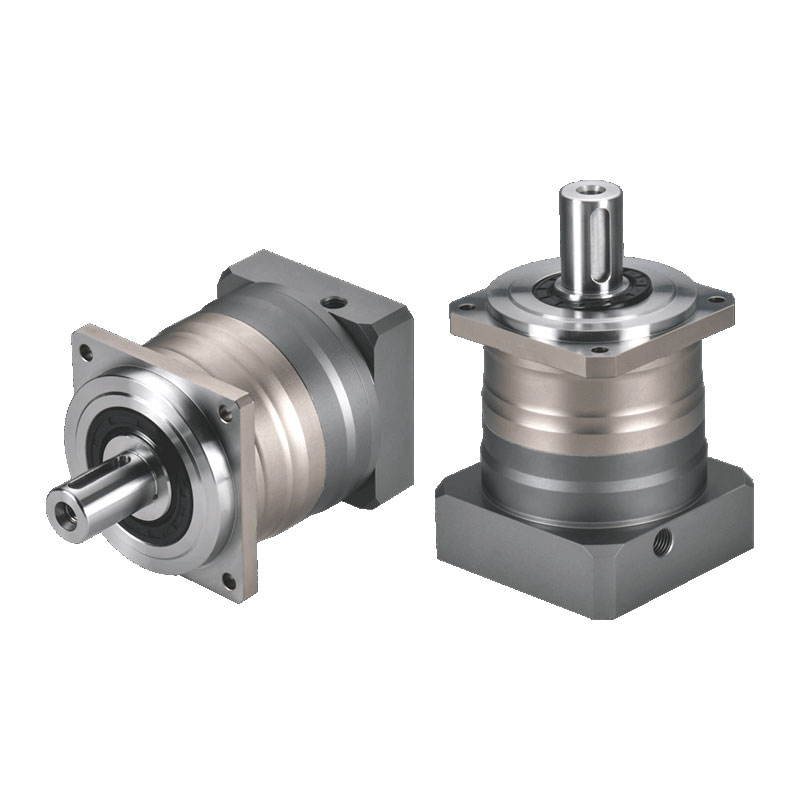

| Solid shaft output mode | ||

| S(Single key shaft) | S1(Smooth output shaft) | T(Custom shaft) |

|

|

According to customers |

2. The input shaft diameter of model 140 is ≤42mm, and input with key is optional.

3. The output shaft diameter of model 140 is ≤55mm.

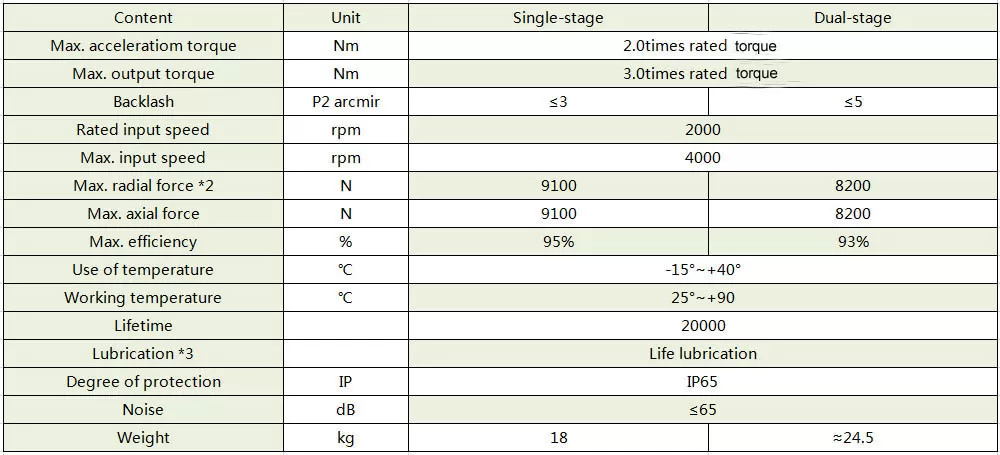

Reduction Ratio

| Series | Single | Dual | ||||||||||||

| Ratio*1 | Recommended | 25 | 35 | |||||||||||

| 3 | 4 | 5 | 7 | 10 | 15 | 20 | 28 | 40 | 50 | 70 | ||||

| Not recommended | 30 | 100 | ||||||||||||

| Nominal torque TN | Nm | 450 | 650 | 650 | 495 | 450 | 650 | 650 | 650 | 450 | 650 | 650 | 490 | 450 |

Reducer Parameters

*1、Ratio i=Nin/Nout (Input speed/output speed)

*2、When the speed of the output shaft of the reducer is100r/min, it acts on the midpoint of the output shaft of the reducer, and the direction of action is perpendicular to the output shaft, meeting the maximum radial force that the output shaft can withstand when the life of the reducer is 20000H.

*3、High/low temperature grease can be customized acco

+86-18664078178

+86-18664078178  Email

Email